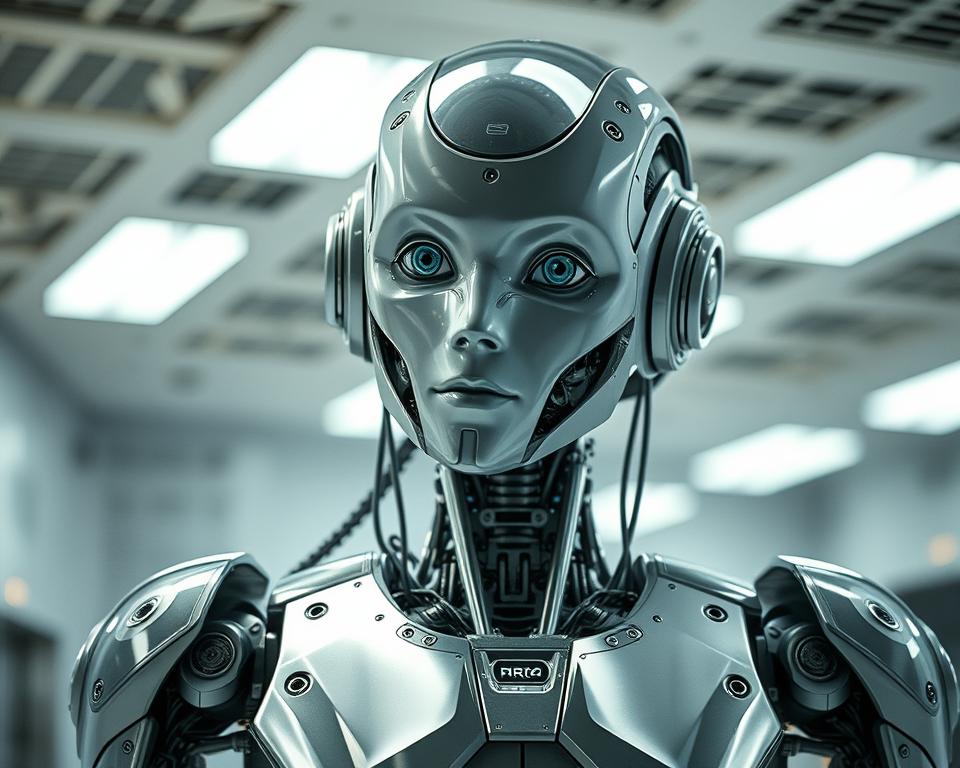

Imagine having a robotic friend to help with daily tasks or just to keep you company. Thanks to robotics technology, making a 3D printed humanoid robot is now possible. This DIY guide will show you how to make your own robot, covering its design and how it works.

This project highlights the power of robotics technology. It also lets you explore robotics, learn about its uses, and see what the future holds.

Key Takeaways

- Understanding the basics of robotics technology

- Learning to design and assemble a 3D printed humanoid robot

- Exploring the applications of humanoid robots in daily life

- Gaining hands-on experience with DIY robotics projects

- Discovering the future prospects of robotics technology

Introduction to 3D Printed Humanoid Robots

3D printing has greatly advanced humanoid robot development. It has opened new paths in robotics. Now, robots can look and act like humans.

These robots are made to interact with us naturally. They are perfect for research, education, and social use. 3D printing makes it possible to create complex designs and precise fabrication. This is key for human-like movements and interactions.

What is a 3D Printed Humanoid Robot?

A 3D printed humanoid robot looks and acts like a human. It’s made layer by layer using 3D printing. This method allows for intricate designs and complex structures that traditional methods can’t achieve.

The ASPIR project is a great example. It’s a full-size humanoid robot with advanced AI. It shows the power of 3D printing in creating complex robots.

Applications of Humanoid Robots

Humanoid robots have many uses. They help in research and development to study how humans and robots interact. They also teach robotics and programming in education. Plus, they assist and provide companionship in social settings.

| Field | Application | Benefits |

|---|---|---|

| Research | Studying human-robot interaction | Understanding human behavior and improving robot design |

| Education | Teaching robotics and programming | Enhancing learning experience with hands-on robotics |

| Social Settings | Providing companionship and assistance | Supporting individuals with social or physical needs |

Humanoid robots are great at getting us to feel emotions. This makes them very useful in places where we need to interact and feel empathy.

Benefits of 3D Printing in Robotics

3D printing has changed how we make robots. It has led to big steps forward in innovative robotics and advanced robotics systems.

One big plus of 3D printing is how it saves money. Old ways of making things can cost a lot and waste materials. But 3D printing makes complex parts cheaper and uses less material.

Cost-Effectiveness

3D printing is cheaper because it doesn’t need molds or a lot of tools. This makes starting a project easier for both hobbyists and pros.

Customization and Personalization

3D printing lets you make parts just for your needs. You can design and print parts for a special robotic arm or a custom case for electronics.

Also, 3D printing can use many materials, like plastics and metals. This means you can make parts with different properties. In robotics, this is really useful because each part might need something different.

Rapid Prototyping

Another great thing about 3D printing is how fast you can make prototypes. Designers can try out their ideas quickly and make changes fast. This is super helpful in robotics, where things need to work well and be precise.

In short, 3D printing in robotics has many benefits. It saves money, lets you customize, and makes prototyping fast. These advantages are helping make robots more advanced and useful.

Essential Tools and Equipment Needed

Making a 3D printed humanoid robot needs careful tool and equipment selection. The right 3D printer and filament are key to success.

3D Printer Selection

Finding the perfect 3D printer is the first step. Look at the printer’s resolution, build volume, and filament compatibility. For robotics engineering, a precise and reliable printer is vital.

| Printer Model | Resolution | Build Volume |

|---|---|---|

| Model A | 0.1 mm | 200x200x200 mm |

| Model B | 0.05 mm | 300x300x300 mm |

An expert says, “The right 3D printer is crucial for your robotics project.”

“The right 3D printer can make all the difference in the precision and durability of your robot’s parts.”

Filament Types

The filament you choose affects the robot’s parts durability and function. PLA, ABS, and PETG filaments have different benefits. For programmable robotics, the right filament boosts performance and life.

- PLA: Biodegradable, easy to print with

- ABS: Strong, impact-resistant

- PETG: Durable, resistant to warping

Software for Design

Designing robot parts needs advanced software. Tinkercad and Fusion 360 are popular choices. They have tools for complex designs.

Choosing software depends on your experience and project needs. Beginners find user-friendly software with tutorials very helpful.

Designing Your Humanoid Robot

Creating a 3D printed humanoid robot starts with a good design. This step is key because it sets the robot’s look, function, and how well it works.

Choosing a Design Software

Picking the right design software is the first step. Popular choices are Blender, Autodesk Fusion360, and Tinkercad. Each has its own strengths and benefits.

| Software | Key Features | User Level |

|---|---|---|

| Blender | Advanced 3D modeling, animation tools | Intermediate to Advanced |

| Autodesk Fusion360 | 3D CAD, CAM, and CAE tools | Intermediate to Advanced |

| Tinkercad | User-friendly interface, simple 3D modeling | Beginner to Intermediate |

Key Design Considerations

When designing your robot, think about its purpose, materials, and design complexity. Also, consider the kinematics and how its parts will move.

- Define the robot’s purpose and functionality

- Choose appropriate materials for durability and weight

- Consider the complexity and feasibility of the design

Preparing Files for Printing

After designing, prepare the files for 3D printing. Export the design into STL or OBJ files. Make sure the files are error-free and optimized for printing.

By designing and preparing files well, you’re ready for a successful 3D printing. This improves the robot’s performance and helps advance cutting-edge robotics and humanoid robot technology.

Printing Your Humanoid Robot Parts

The ASPIR project needed over 300 hours of 3D printing. This shows how complex and time-consuming it is to print humanoid robot parts. Knowing the 3D printing process is key to getting good results.

Tips for a Successful Print

To print well, you must calibrate your 3D printer right. Adjust settings like layer height and infill density to fit your robot’s parts.

The choice of filament is also crucial. Different materials affect your robot’s parts’ durability and function. PLA is good for beginners because it’s easy to use and doesn’t warp much.

- Make sure the print bed is level and clean.

- Choose the right filament for each part.

- Watch the print for any problems.

Common Printing Issues and Solutions

Even with careful planning, printing problems can happen. Layer shifting and warping are common. You can fix these by tweaking your printer settings and making sure the print bed sticks well.

For layer shifting, check your belts and print speed. Warping can be lessened with a brim or raft and the right bed temperature.

| Issue | Solution |

|---|---|

| Layer Shifting | Tighten belts, reduce print speed |

| Warping | Use brim or raft, adjust bed temperature |

By following these tips and knowing how to solve common problems, you can make your 3D printed humanoid robot parts better. This will help bring your robotics project to life.

Assembling the Robot

The ASPIR robot has 33 degrees of freedom, making it a fun but tough project for robotics fans. Building a humanoid robot needs careful attention and a clear plan.

Step-by-Step Assembly Guide

To build your 3D printed humanoid robot, just follow these steps:

- Prepare all the printed parts and make sure they’re clean.

- Assemble the mechanical components as your design says.

- Secure all joints and limbs for stability and movement.

A detailed guide is key for a good build. Always check your design plans for exact steps.

| Component | Description | Quantity |

|---|---|---|

| Body Frame | Main structural part | 1 |

| Limb Segments | Parts for arms and legs | 4 |

| Joint Connectors | For linking limb parts | 6 |

Wiring and Electronics Setup

Setting up wiring and electronics is vital for the robot’s work. Make sure all parts fit and are connected right.

Wiring Tips:

- Choose the right wire sizes for your parts.

- Keep your wiring tidy to avoid mess and shorts.

- Check your connections before turning on the robot.

“The mix of electronics and wiring in robotics needs a good grasp of both mechanical and electrical parts.”

Programming Your Humanoid Robot

Programming a humanoid robot is an exciting journey. It combines innovative robotics with advanced robotics systems. First, you need to learn the basics of robot programming.

Introduction to Robot Programming

Robot programming means writing code for the robot to follow. For humanoid robots, this includes movements and interactions. The ASPIR project uses Arduino Mega2560 and Arduino Mega Servo Shield for programming.

Programming Languages and Tools

Many programming languages and tools are available. For example, Arduino uses a simplified C/C++. Other popular choices are Python and C++. The choice depends on the robot’s hardware and task complexity.

| Programming Language | Hardware Compatibility | Complexity |

|---|---|---|

| Arduino (C/C++) | Arduino Boards | Low to Medium |

| Python | Raspberry Pi, Arduino | Medium to High |

| C++ | Various Microcontrollers | High |

Basic Movements and Functions

To program basic movements, you need to control the robot’s servos and motors. For example, the Arduino Mega Servo Shield lets you control multiple servos precisely. Here’s how to start a servo motor with Arduino:

Servo myservo; myservo.attach(9);

Basic functions include walking, gesturing, or simple interactions. The goal is to break these movements into easy-to-handle code segments.

Mastering these basics lets you tackle more complex tasks. You can integrate sensors and even AI-driven behaviors.

Testing and Troubleshooting

After building your 3D printed humanoid robot, it’s time to test and fix any problems. This step is key in robotics engineering. It helps find and solve issues that could harm the robot’s performance.

Conducting Initial Tests

First, check if the robot works right. Make sure all parts move as they should. Also, test the robot’s programmable robotics to see if it follows commands well.

- Look for any mechanical problems, like loose parts or parts that aren’t aligned right.

- Test the robot’s sensors and feedback loops to make sure they’re working right.

- Make sure the robot’s power supply is steady and strong enough.

Common Issues and Fixes

While testing, you might run into some common problems. Here are some solutions for these issues:

- Motor Issues: If a motor doesn’t work, check the wires and connections. Make sure the motor is set up right in the robot’s program.

- Sensor Malfunctions: If a sensor isn’t giving accurate data, try calibrating it again. Look for any blockages or interference that might be causing the problem.

- Structural Weakness: If the robot’s structure is weak or unstable, you might need to add more materials or redesign some parts.

By testing and fixing your humanoid robot carefully, you can make sure it works well. This will help it do more advanced things in programmable robotics.

Advanced Features for Humanoid Robots

Humanoid robots are getting smarter with AI and sensors. These upgrades make them more interactive and responsive. They can now handle complex tasks better than before.

Adding Sensors and Feedback Loops

Sensors help humanoid robots understand their environment. They use different sensors like touch, sight, and sound. This lets them interact better with their surroundings.

Feedback loops are key for precise robot movements. They help the robot adjust its actions. This improves its performance and stability.

| Sensor Type | Functionality | Benefits |

|---|---|---|

| Tactile Sensors | Detect touch and pressure | Enhance manipulation capabilities |

| Visual Sensors | Capture and interpret visual data | Improve navigation and object recognition |

| Auditory Sensors | Detect and interpret sound | Enable voice command recognition |

Integrating AI for Enhanced Behavior

The ASPIR project shows how AI and sensors improve robot behavior. AI lets robots learn and adapt. This boosts their autonomy and function.

AI-driven enhancements include better decision-making and interaction. Robots can now do complex tasks more precisely.

The future of humanoid robots depends on AI and sensor tech. As these areas advance, robots will get smarter. They’ll be able to do many tasks more efficiently and accurately.

Case Studies: Successful 3D Printed Robots

3D printed robots are changing the world of robotics. They show how 3D printing can make complex robots. They also show new ways to use this technology.

Inspirational Examples

The ASPIR project is a great example. It’s a 3D printed humanoid robot that has caught a lot of attention. It shows that 3D printing can make advanced robots.

“The ASPIR project showcases the potential of 3D printing in robotics, enabling the creation of complex robots with enhanced functionality.”

Another example is 3D printing prosthetic limbs. These are not humanoid robots, but they show how 3D printing can make precise mechanical parts.

| Project | Application | Key Features |

|---|---|---|

| ASPIR | Humanoid Robot | Advanced AI, 3D printed components |

| Prosthetic Limbs | Medical Prosthetics | Customizable, precise, durable |

Lessons Learned from Real Projects

These projects teach us a lot. First, design flexibility is key. 3D printing lets us make shapes that traditional methods can’t.

Second, choosing the right materials is important. The parts’ durability and function depend on the materials used.

Lastly, adding electronics and software is vital. Projects like ASPIR show we need smart programming and control systems.

Key Takeaways:

- Design flexibility is crucial in 3D printed robotics projects.

- Material selection significantly impacts the durability and functionality of 3D printed parts.

- Advanced electronics and software integration are essential for the functionality of 3D printed robots.

Safety Considerations in Robotics Projects

Keeping safety in mind is key when working on robotics projects. This is true, even more so with artificial intelligence and humanoid robot design. Robotics projects often use complex tools and materials. It’s important to know how to handle them safely.

When you’re working with robotics, you need to watch out for dangers. These dangers can be electrical, mechanical, or related to software. By following safety rules, you can lower these risks. This makes your work area safer.

Safe Handling of Tools and Materials

It’s crucial to handle tools and materials safely in robotics projects. Here are some important tips:

- Always wear protective gear, like safety glasses and gloves, when working with dangerous materials or tools.

- Make sure your workspace has good air flow, which is important when working with chemicals or materials that give off fumes.

- Learn how to use and take care of tools properly to avoid accidents.

Best Practices for Electronics

Electronics are a big part of robotics projects. Following best practices can help avoid electrical shocks, fires, and other dangers.

- Use the right power sources and make sure all electrical parts are safe for what you’re doing.

- Keep your workspace tidy to avoid electrical dangers like short circuits.

- Check your electronics and wiring often for any signs of wear or damage.

By following these safety tips, you can have a safe and successful time working on robotics projects. This includes projects that use 3D printing and artificial intelligence.

Future Trends in 3D Printed Humanoid Robots

Technology keeps getting better, making 3D printed humanoid robots more advanced. These robots are leading the way in robotics. Many trends will shape their future.

Innovations on the Horizon

Several new things are coming for 3D printed humanoid robots. These include:

- Advanced Materials: New materials are being made. They are stronger and more flexible. This lets robots be more complex.

- Improved Printing Techniques: 3D printing is getting better. It’s now faster and more precise. This means robots can be made quicker and cheaper.

- Modular Designs: Robots are now designed to be easy to change. You can upgrade or modify them easily.

The Role of AI and Machine Learning

AI and machine learning will change 3D printed humanoid robots a lot. They will make robots more independent, smart, and able to interact better. Here’s how:

- Enhanced Autonomy: AI will let robots make their own decisions. They will act based on their surroundings and tasks.

- Improved Human-Robot Interaction: Robots will understand and respond to human feelings and commands better. This is thanks to machine learning.

- Predictive Maintenance: AI will help find problems before they get big. This means robots will work better and have less downtime.

Adding AI and machine learning to 3D printed humanoid robots will lead to big improvements. We will see more advanced and capable robots.

Resources for Aspiring Robot Builders

Building a 3D printed humanoid robot needs technical skills and the right resources. Aspiring robot builders can find help in online communities, forums, and educational materials. These resources help improve knowledge and skills in robotics engineering and programmable robotics.

Online Communities and Forums

Online platforms are great for connecting with other robotics fans. They offer a place to share knowledge and solve problems. Some top online communities include:

- Reddit’s r/Robotics: A lively community for robotics discussions.

- Stack Overflow: Helps with programming questions, including robotics.

- Robotics Stack Exchange: A Q&A site for robotics.

These forums are perfect for getting feedback on your projects. You can learn from others and keep up with robotics trends.

Recommended Books and Tutorials

For a deeper dive into robotics, check out these books and tutorials:

| Resource | Description | Level |

|---|---|---|

| “Robotics, Vision & Intelligence” | A detailed guide to robotics, covering theory and practice. | Advanced |

| “Programming Robots with ROS” | A hands-on intro to robot programming with ROS. | Intermediate |

| ROS Tutorials | Official ROS tutorials on robot programming. | Beginner to Advanced |

These resources cater to learners at all levels. They help beginners to advanced users in programmable robotics.

By using these resources, aspiring robot builders can improve their skills. They can also keep up with the latest in robotics engineering.

Conclusion

Building a 3D printed humanoid robot is a complex yet rewarding project. It combines cutting-edge robotics and innovative manufacturing techniques. This DIY guide has shown you the essential steps, from designing and printing parts to assembling and programming your robot.

Key Takeaways

Creating a functional humanoid robot requires several key components. These include selecting the right 3D printing technology and designing for printability. You also need to integrate electronics and programming. By understanding these elements, you can successfully bring your robot to life.

Exploring New Frontiers

Humanoid robot technology is evolving, opening up new possibilities. It can be used in healthcare, education, and service industries. By embracing this technology, enthusiasts and professionals can contribute to advancements in cutting-edge robotics. This pushes the boundaries of what is possible with 3D printing and robotics.

FAQ

What is a 3D printed humanoid robot?

A 3D printed humanoid robot looks like a human and is made by 3D printing. This tech lets us create complex shapes and designs.

What are the benefits of using 3D printing in robotics?

3D printing in robotics saves money, allows for customization, and speeds up making prototypes. It helps create complex designs for specific tasks.

What software is used for designing 3D printed humanoid robots?

Designing these robots uses software like Tinkercad, Fusion 360, and Blender. These tools help make detailed designs and models.

How do I choose the right 3D printer for my humanoid robot project?

Look at the printer’s resolution, build volume, and filament types. Also, check if it can handle complex designs.

What are some common issues with 3D printing humanoid robot parts, and how can they be resolved?

Issues like warping and adhesion problems can happen. Fixing them involves adjusting settings, using adhesion materials, and calibrating the printer.

How do I program my 3D printed humanoid robot?

Use programming languages like Python or C++. You’ll also need software for robotics and AI to program it.

What safety considerations should I keep in mind when working on a 3D printed humanoid robot project?

Always handle tools safely and wear protective gear. Follow best practices for electronics to avoid electrical shock.

Can I integrate AI and machine learning into my 3D printed humanoid robot?

Yes, you can add AI and machine learning. This lets the robot recognize objects, understand speech, and make decisions.

Where can I find resources and communities for 3D printed humanoid robot projects?

Look online for forums, social media groups, and robotics websites. There are also tutorials and documentation for software and hardware.

What are some potential applications of 3D printed humanoid robots?

These robots can be used in research, education, healthcare, and entertainment. They can interact with humans, perform tasks, and assist.