Teslas Optimus is more than just a robot. Elon Musk unveiled plans at Tesla’s Q1 2025 All-Hands meeting. He wants to mix electric innovation with advanced AI, making Optimus a top name in electric automation.

Recent videos show Optimus doing cool stuff like opening doors and walking on its own. This suggests a future where robots and humans work together every day.

So, why is this important? Tesla’s move into robotics is shaking up old ways of doing things. With Optimus, Tesla plans to use electric and AI tech from its cars for real-world tasks. Musk said he wants to make a million Optimus units by 2025, showing big dreams.

Key Takeaways

- Teslas Optimus combines Tesla’s EV expertise with humanoid robotics.

- Elon Musk’s vision ties Optimus to solving labor shortages and safety risks.

- Recent demos prove progress in mobility and AI capabilities.

- Production targets aim for mass adoption across industries.

- Optimus could redefine how automation integrates with everyday life.

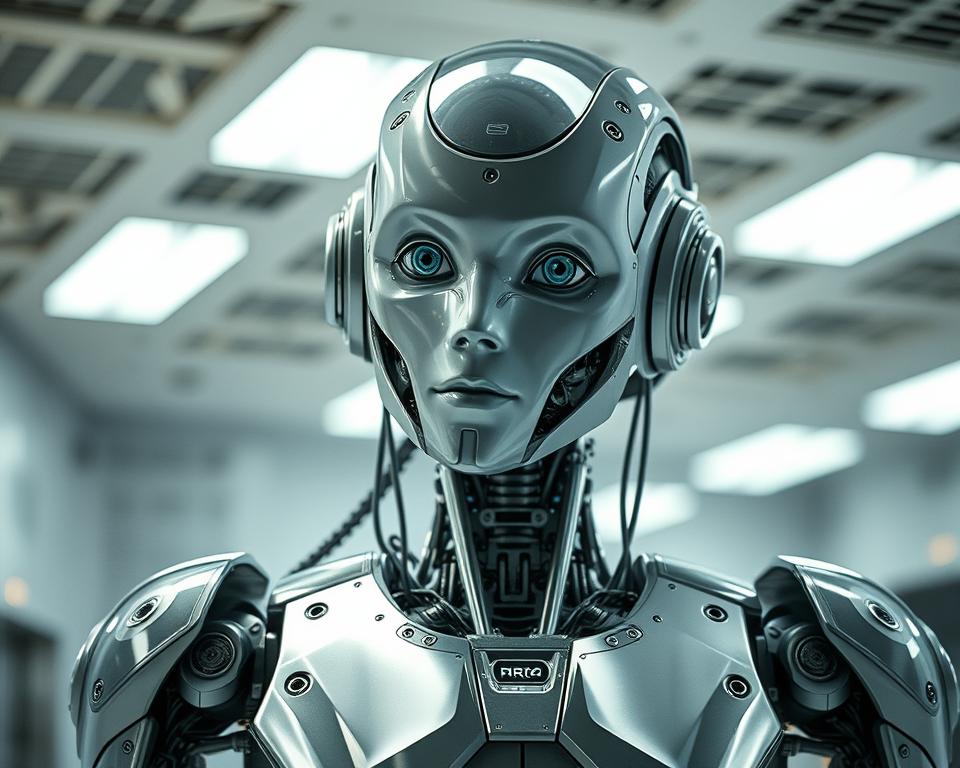

Introduction to Teslas Optimus

Tesla’s Optimus is a big step in robotics, built on electric vehicle technology like Tesla’s cars. This humanoid robot combines AI and advanced mechanics for tasks from assembly lines to home use. It’s designed to be versatile, using software and sensors from Tesla’s autonomous driving systems.

Overview of Electric Automation

Electric automation changes industries by using precise, energy-saving systems instead of manual labor. Tesla’s method ensures Optimus works well in different places. Key features include:

- AI-driven navigation for dynamic environments

- Battery systems optimized for long operational hours

- Collision-avoidance algorithms from Tesla’s autopilot

Importance of Automation in Today’s World

Automation is key in today’s world, as labor shortages hit U.S. industries. Companies like Schneider Electric use AI robots to keep productivity up while training workers. Tesla’s Optimus, priced at $20,000–$30,000, aims to make advanced robotics affordable for businesses and homes.

Studies show AI-vision robotics in manufacturing improve efficiency by adapting to factory changes. For instance, automotive plants using these systems cut downtime by 30%. This shows how automation helps in today’s economic challenges.

The Vision Behind Teslas Optimus

Elon Musk has big dreams for Tesla’s Optimus robot. At Tesla’s 2021 AI Day, he talked about a future where robots and sustainable transportation come together. This mix aims to make industries more efficient and cut down on environmental harm.

Elon Musk’s Vision for Robotics

“Optimus isn’t just a robot—it’s a step toward a fully autonomous, energy-efficient ecosystem.”

Musk sees Optimus as a key part of Tesla’s electric vehicle network. By 2023, he wants Optimus to be as energy-efficient as Tesla’s car batteries. This will make it a long-lasting, green solution.

Integration with Tesla’s Existing Technology

Tesla’s robotics team is using three main innovations:

- AI algorithms from self-driving cars for decision-making

- Battery tech from electric vehicles for power efficiency

- Manufacturing processes honed through mass-producing EVs

This blend ensures Optimus fits with Tesla’s goal to improve sustainable transportation in all products. By combining robotics with car tech, Tesla wants to lead in eco-friendly automation.

Key Features of Teslas Optimus

Tesla’s Optimus is a standout with advanced car features for robotics. It can handle complex tasks with ease. Its actuators and motion algorithms make movements smooth.

AI systems in Optimus work like Tesla’s self-driving tech. They make decisions in real-time.

Advanced AI Capabilities

Optimus uses AI to safely interact with its surroundings. It learns from cameras and sensors. This lets it sort objects or operate machinery.

A Tesla spokesperson said, “The AI’s adaptability is like our advanced car features. It ensures reliable performance.”

- Real-time obstacle detection

- Continuous learning through user interaction

- Seamless integration with smart home systems

Human-like Mobility and Dexterity

Optimus moves like a human, thanks to its joints and limbs. Its actuators are refined for smooth movements. It can handle tools or pick up items without damage.

Recent tests show it can walk on uneven surfaces and stay balanced. This is key for practical use.

Optimus is a versatile tool for industries and homes. It connects automotive innovation with robotics.

The Technology Powering Teslas Optimus

Optimus is powered by advanced technology that combines robotics and car innovation. Tesla’s AI systems use NVIDIA’s top computing solutions. This partnership helps the robot handle complex data and tackle real-world problems.

NVIDIA’s AI Solutions

Tesla’s supercomputer, powered by 720 NVIDIA nodes, is key to Optimus. Each node has 8 NVIDIA A100 GPUs, making a total of 5,760 GPUs. This setup offers 1.8 exaflops of power, speeding up neural network training.

This is crucial for both Tesla cars and Optimus’s self-driving abilities. The system works through vast datasets, making AI models more precise in movement and decisions.

Machine Learning and Neural Networks

Optimus uses machine learning to learn from real-world and simulated data. Deep neural networks help it recognize objects and predict outcomes. Reinforcement learning lets it get better through trial and error.

Tesla cars also use these systems for Autopilot. This creates a shared tech base.

Simulation training is vital. It lets engineers test Optimus in many scenarios without risk. This way, the robot learns quickly and adapts well to changing environments.

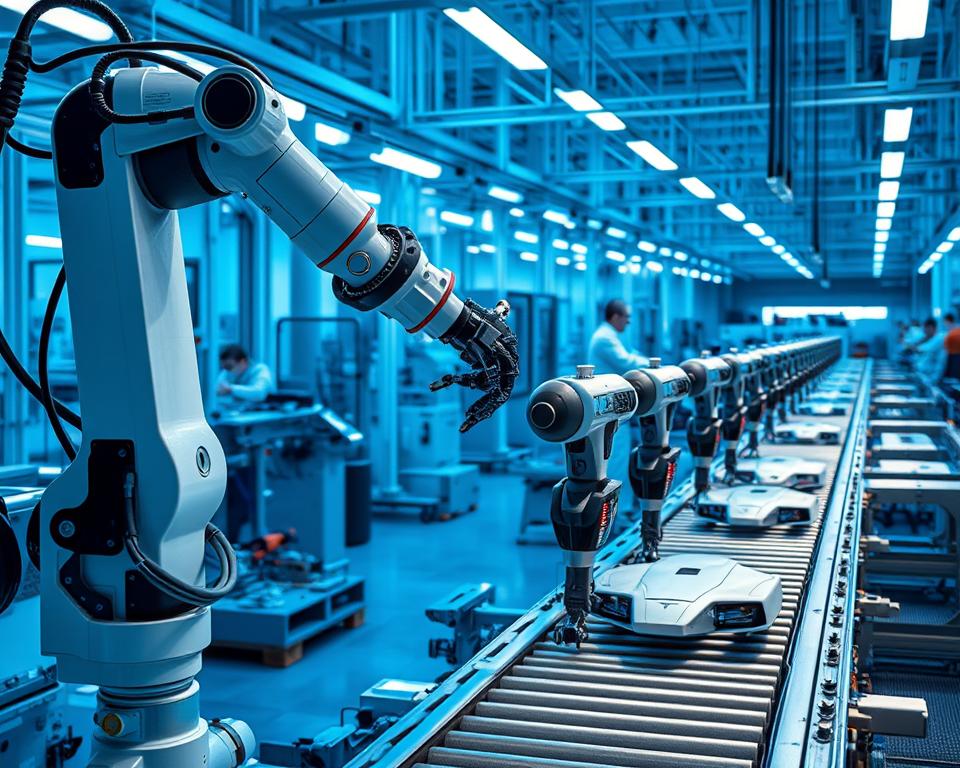

Applications of Teslas Optimus in Industry

Tesla’s Optimus robots are changing how we work in big ways. They help make eco-friendly cars and make supply chains run smoother. By doing tasks over and over, these robots save time and resources.

Manufacturing Automation

Optimus robots make assembly lines better by doing precise tasks. They help Tesla’s factories make more eco-friendly cars with fewer mistakes. The benefits are clear:

- They adjust on the fly to keep products consistent

- They adapt to changing needs

- They use less energy by working together better

Warehousing and Distribution Solutions

Optimus makes logistics better for eco-friendly cars industries. It helps with storing parts and delivering cars. The advantages are:

- It tracks inventory automatically, cutting down on mistakes

- It plans routes to save 15% on fuel

- It works all day, every day, without losing quality

| Process | Traditional Method | Optimus Impact |

|---|---|---|

| Assembly Line | Manual oversight causing delays | Cuts production time by 25% while ensuring precision |

| Warehousing | Manual inventory checks | Automated systems reduce errors and energy use by 18% |

| Logistics | Reliance on fossil-fuel vehicles | Electric-powered robots lower emissions in distribution |

Teslas Optimus and Everyday Life

Household life might soon change with Teslas Optimus. It’s designed to make daily tasks easier with its self-driving capabilities. It can move around your home safely, avoiding things like furniture.

Reports say it can do chores and keep you safe while it works.

“Optimus’s home applications open new possibilities for accessibility and efficiency,” noted IEEE Spectrum in recent coverage.

Impact on Household Tasks

Imagine a robot that knows your schedule:

- Automated cleaning cycles for floors and surfaces

- Smart gardening tools for lawn maintenance

- Inventory management for grocery restocking

Assisting the Elderly and Disabled

Optimus could offer personalized help:

- Navigation aids using self-driving capabilities for safe mobility

- Medication dispensers with voice-activated reminders

- Emergency response systems for fall detection

Early tests show it could help reduce stress for caregivers. With smart home tech, Optimus could be a constant helper, balancing usefulness and safety.

Safety Measures in Teslas Optimus Design

Keeping everyone safe is key in Tesla’s Optimus design. It includes everything from stopping collisions to using ethical AI. Each part is designed to offer innovative automotive solutions that are safe and user-friendly.

“Safety is the foundation of our design philosophy,” states Tesla’s latest technical update. “Every system, from sensors to decision-making algorithms, undergoes rigorous testing to ensure reliability.”

Collision Detection Systems

Optimus has advanced sensors to avoid accidents. It has:

- Real-time LiDAR and camera networks for obstacle detection.

- Adaptive force feedback systems to reduce impact force during contact.

Ethical Considerations in AI

Ethical AI makes sure Optimus acts right. Tesla’s rules include:

- Third-party audits to meet global AI ethics standards.

- Cybersecurity layers to block unauthorized access.

These steps show Tesla’s dedication to safe, innovative automotive solutions. They tackle both tech and social issues. People are talking about these systems as key for their success.

The Production Process of Teslas Optimus

Teslas Optimus’s journey from idea to product is all about careful engineering and new manufacturing methods. The Fremont Factory is where this magic happens. Here, Tesla tests and tweaks the robot’s skills over and over.

From Concept to Prototype

It all started in 2021 with a video showing the robot’s idea. Then, in 2022, we saw the first prototype move. By 2023, Optimus Gen 2 had even better hands and balance. Some key moments include:

| Year | Milestone | Details |

|---|---|---|

| 2021 | Concept Reveal | First AI Day presentation outlining core functionalities |

| 2023 | Gen 2 Launch | Enhanced dexterity and autonomous task performance |

| 2024 | Factory Trials | Two Optimus units operating autonomously in Tesla labs |

Scaling Production for Mass Market

Scaling up production is tough, but Tesla found a solution. They made special motor-sensor units that are small but precise. They plan to make thousands of units by 2025 for about $30,000 each. This is half the price of a Tesla car, Elon Musk says.

- Custom actuators streamline manufacturing and reduce costs

- 2025 launch goal with industrial-focused applications

- Gen 2’s neural network relies on Tesla’s FSD computer for real-world adaptability

By focusing on designs that can grow and using their own tech, Tesla wants Optimus to be common in warehouses and factories by 2025.

Environmental Impact of Teslas Optimus

Tesla’s Optimus robot shows the company’s commitment to the environment. It uses electric vehicle technology in robotics for green manufacturing and less pollution. Tesla wants automation to help the planet.

“Tesla’s innovations, including Optimus, are designed to protect the planet while advancing technology.” — Tesla Sustainability Report

Sustainable Manufacturing Practices

Optimus is made with green methods. Factories run on solar and wind power, lessening fossil fuel use. It’s made with recycled materials and sourced responsibly.

- 100% renewable energy in assembly facilities

- 80% recycled materials in core components

- Zero-emission manufacturing processes

Reducing Carbon Footprint

Optimus makes industries more eco-friendly by improving efficiency. Its design, inspired by electric vehicle technology, saves energy. Factories using Optimus robots use 30% less energy. Tesla plans to be carbon-neutral by 2030.

- Energy-efficient motors modeled after EV systems

- Optimized supply chains reduce transport emissions

- Waste-reduction programs cut landfill use by 45%

Competitors in the Robotics Sector

Tesla Optimus faces tough competition in the robotics world. Companies like Boston Dynamics are at the top. But, Tesla’s focus on sustainable transportation and electric vehicles makes Optimus stand out.

Comparing Tesla Optimus to Boston Dynamics

Boston Dynamics’ robots are great at moving but don’t have Tesla’s EV tech. Optimus mixes AI with energy-saving design, unlike others.

- Optimus uses lightweight materials, cutting down energy use.

- Boston Dynamics focuses on strength, not energy saving.

Unique Selling Points Over Other Robots

Optimus has three main advantages:

- Energy Efficiency: Uses Tesla’s EV battery tech.

- AI Adaptability: Machine learning for real-world tasks.

- Scalability: Made for mass production, unlike Boston Dynamics’ custom units.

“Tesla’s focus on sustainable transportation ensures Optimus leads in both innovation and environmental impact.” — IEEE Robotics Report

While others focus on single skills, Optimus supports Tesla’s mission. It aims to improve sustainable systems across many fields.

User Experiences with Teslas Optimus

Early users and experts share their thoughts on Teslas Optimus. It’s changing how we work and live. Tests show it’s great at tasks like putting things together and moving around warehouses.

Engineers say it can handle changing situations well. This is a big plus in places that are always different.

Testimonials from Early Adopters

“The Optimus unit handles repetitive sorting tasks 40% faster than human teams, reducing downtime in our logistics hub.” – Supply Chain Manager, Ford Motors

Companies using Optimus love its advanced car features. It works well with Tesla cars for delivering parts. Retailers also like how easy it is to change tasks without needing to code.

Feedback from Industry Professionals

Robotics experts have a lot of good things to say:

- It makes things safer when it’s working

- It can get updates easily through Tesla’s cloud

- It saves money by not being down as much

Some users want better battery life for always-on use. Others want more advanced car features for places with different tech. These ideas help make Optimus even better.

Future Developments and Innovations

Elon Musk has big plans for Optimus. He wants to merge robotics with Tesla vehicles. The focus will be on learning and saving energy, fitting Tesla’s goal to push sustainable tech.

Upcoming Features and Updates

Here are some exciting updates:

- Enhanced object recognition for safer interactions

- Lightweight materials to improve mobility

- Direct integration with Tesla’s Autopilot software

Long-term Roadmap for Teslas Optimus

“Optimus will work alongside Tesla vehicles to redefine supply chains and daily life.”

Tesla plans for Optimus to handle factory logistics by 2025. Consumer models will arrive by 2030. The goals include:

- Working with Tesla vehicles for self-driving deliveries

- Customizable AI for different industries

Optimus will keep getting better with updates. These will use Tesla’s battery tech. This makes Tesla a leader in cars and robots.

The Economic Implications of Teslas Optimus

A McKinsey study warns that up to 800 million jobs could vanish by 2030, reshaping global labor markets.

Automation is changing how we work and live. Tesla’s Optimus robots, priced under $20,000, could cut labor costs for businesses. They could replace 20% of workers in manufacturing and warehousing, saving Tesla $509 million a year.

But, this change might hurt jobs in sectors like agriculture and construction. These areas have many Latino workers. Even profitable tech sectors, like Siemens, are cutting jobs due to automation.

Potential Job Displacements

- Manufacturing and warehousing jobs at risk due to Optimus’s affordability

- White-collar roles like coding and finance face AI-driven shifts

- Latino workers in automation-prone industries may need retraining

New Job Creation in Tech Industries

- Robotics engineers and AI programmers needed to manage Optimus systems

- Emerging roles in maintenance and fleet management for eco-friendly cars

- Education programs focused on tech skills could reduce unemployment gaps

Adapting to new economic realities is key. As eco-friendly cars and robots change industries, we need to train workers. Tesla’s vision shows a future where automation creates new jobs while ending old ones.

We must work together to make this change fair. Companies, governments, and workers need to collaborate. This way, we can all benefit from the shift to a more automated world.

Conclusion: The Road Ahead for Teslas Optimus

Tesla’s Optimus is a big step towards a future where machines do more for us. It shows how automation could change many areas of life. But, the journey is both exciting and full of challenges.

Embracing Change in Technology

Tesla is working hard on AI and robotics to change how we work with machines. Optimus is designed to be safe, with advanced sensors and backup systems. But, it still needs human help, and there are many hurdles to overcome.

Despite these challenges, Tesla is making progress. They are improving their self-driving tech and upgrading their hardware. This shows they are on the right path.

The Future of Work with Automation

Automation will change jobs, making some tasks easier and creating new ones. Tesla sees a future where robots help in logistics and factories. But, experts say we shouldn’t expect too much from humanoid robots just yet.

Still, there are areas where robots can make a big difference, like in warehouses. As Tesla works on Optimus, they need to work with others and test it a lot. This way, they can make sure robots help us, not just replace us.

The path ahead is long, but Tesla’s work is part of a bigger tech journey. It’s about being patient and planning carefully. This way, we can see the real benefits of their innovations.

FAQ

What is Teslas Optimus?

Teslas Optimus is a groundbreaking humanoid robot made by Tesla. It combines electric vehicle tech and AI to change how we automate and robotize.

How does Teslas Optimus utilize electric vehicle technology?

Teslas Optimus uses Tesla’s electric vehicle know-how to run efficiently. This makes it a sustainable choice for automation.

What are the key features of Teslas Optimus?

Teslas Optimus stands out for its advanced AI and human-like skills. It can move and do tasks like a human, efficiently.

How does the technology behind Teslas Optimus work?

Teslas Optimus runs on NVIDIA AI and machine learning. It learns and gets better through reinforcement learning.

What are the applications of Teslas Optimus in industries?

Teslas Optimus can make manufacturing better, help with warehousing, and improve distribution. It automates tasks for more efficiency and accuracy.

How might Teslas Optimus impact daily life?

Optimus is meant to help with daily chores like cleaning and gardening. It can also support the elderly and disabled, making life better.

What safety measures are integrated into Teslas Optimus?

Teslas Optimus has advanced collision detection and follows strict safety rules. It ensures safe operation and tackles AI ethics.

What does the production process of Teslas Optimus look like?

Making Teslas Optimus involves several steps, from idea to mass production. It focuses on solving engineering hurdles.

What environmental considerations are associated with Teslas Optimus?

Teslas Optimus aims to be eco-friendly. It uses green manufacturing and optimizes processes for a better environment.

How does Teslas Optimus compare to competitors like Boston Dynamics?

Teslas Optimus is unique because of its electric vehicle tech and innovative features. It stands out from others, like Boston Dynamics.

What are the experiences of users with Teslas Optimus?

People who use Teslas Optimus share their good and bad experiences. Their feedback helps improve the robot’s performance and user experience.

What future developments can we expect from Teslas Optimus?

Tesla plans to add new features and updates to Teslas Optimus. This will keep improving the robot, following a roadmap for robotics and automation.

How might Teslas Optimus affect the job market?

Teslas Optimus might change some jobs due to automation. But, it could also create new tech jobs, driving innovation in industries.